PREPARE YOUR SUBSTRATE—Before applying any epoxy, the concrete must be prepared by grinding, filling cracks (if necessary), and then diamond grinding the field and edges. Wood floors are prepared by sanding. Preparation varies depending on the condition of the substrate.

Pro Tip: Conduct moisture testing 72 hours before grinding concrete.

MOISTURE VAPOR TRANSMISSION PRIMER COAT — If moisture vapor transmission (MVT) above 3 lbs. is present, a special MVT primer can take care of that. MVT primer cannot be tinted. If using an MVT primer, an additional primer coat product should be used on top, and that layer should be tinted a solid color.

| STANDARD EPOXY SYSTEM (Solid Color or Metallic) | BROADCAST EPOXY SYSTEM (Flake, Quartz, or other) | |

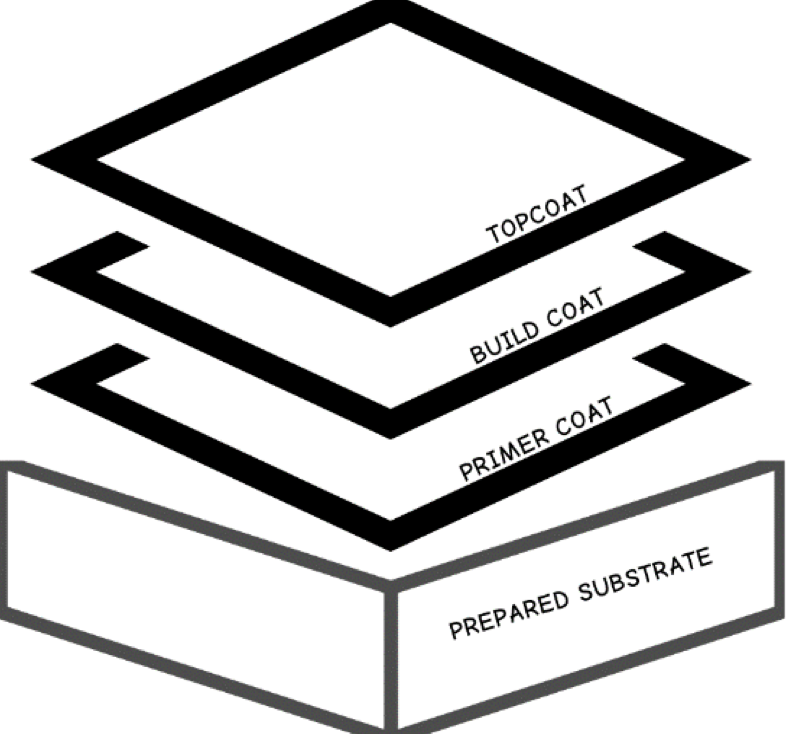

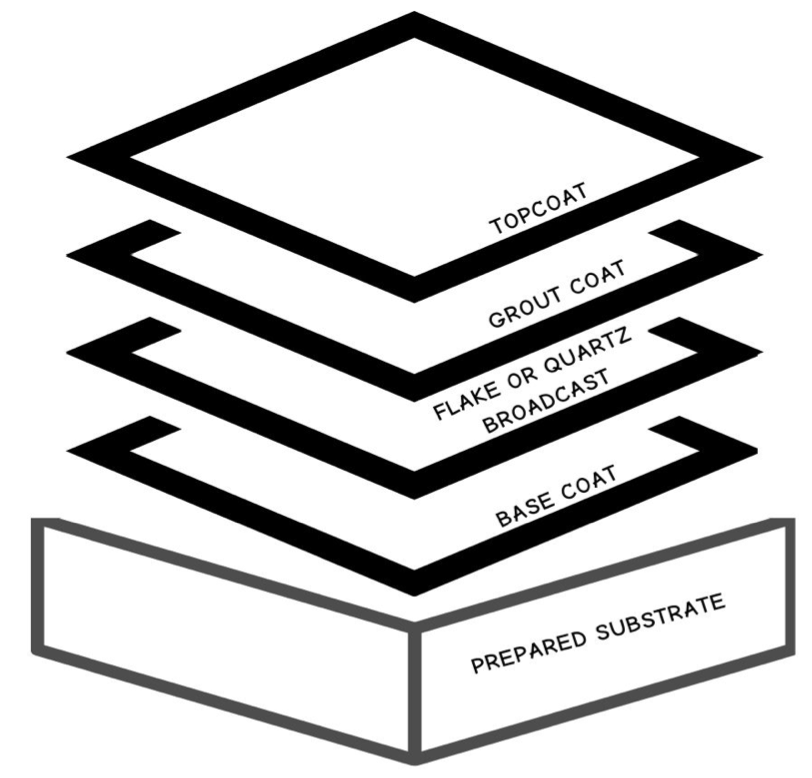

PRIMER COAT—Concrete is porous, so it is imperative to coat with a primer prior to applying build and topcoats. This is true of other substrates as well. A primer reduces bubbles or outgassing. A solid color tint added to the primer is recommended. BUILD COAT—As the middle layer, the build coat is the main body of the system, providing the desired level of thickness and contributing to weight-bearing and impact resistance. Solid color tints or metallic pigments are usually incorporated into this layer. TOPCOAT—This last layer is the most critical for durability and for chemical, stain, and slip resistance. Anti-slip additive can be added. Colorants or glitter can be incorporated to provide a desired esthetic, but the topcoat is usually applied clear. A good topcoat takes the brunt of the wear, and years later, if needed, it can be sanded and re-topcoated without having to re-do the primer and build coats. This layer is applied very thinly. | BASE COAT— This coat serves as both the primer and build coat you would see in a standard system. A solid color tint added to the base coat is recommended. FLAKE OR QUARTZ BROADCAST—Material is broadcasted into the base coat while it is wet. Once dry, exess broadcast material is scraped off and the floor is sanded with sandscreens. GROUT COAT—This layer is applied clear, so the broadcast beneath it can be seen. Product is applied thickly to reduce the rough texture of the broadcasted material. TOPCOAT—This last layer is the most critical for durability and for chemical, stain, and slip resistance. Anti-slip additive can be added. Colorants or glitter can be incorporated to provide a desired esthetic, but the topcoat is usually applied clear. A good topcoat takes the brunt of the wear, and years later, if needed, it can be sanded and re-topcoated without having to re-do the underlying layers. This layer is applied very thinly. | |

|  |