Epoxy flooring is a great solution for residential and commercial applications where a beautiful finish and tough surface are desired. However, excess moisture can cause problems with even the strongest of substances – and epoxy is no exception. Even though your concrete may look dry on the surface, that doesn’t necessarily mean it is dry throughout. It’s important to understand how to properly deal with that moisture.

What is Moisture Vapor Transmission (MVT)?

Concrete is porous by nature and, even though the moisture near the surface of the concrete evaporates as it cures, moisture from below the surface will migrate up through pores, to escape through the path of least resistance. This process is referred to as MVT. This water vapor then breaks down flooring coating systems.

Flooring failures due to MVT costs the construction industry and facility owners billions of dollars each year. MVT problems attack impervious and permeable flooring materials including wood, vinyl, tile, urethane, epoxy, and carpet. The result is disbondment, blistering, pinholes, chipping and pitting, adhesive reversion, cracking, and heaving. If left untreated, it can introduce health concerns associated with Sick Building Syndrome – by aiding the growth of algae, bacteria, mildew, and mold, as well as inducing rot.

Although it may seem as if moisture issues only occur within newly poured concrete, older concrete slabs can also require moisture mitigation. If the concrete was not allowed to cure properly when it was originally poured, too much water was in the mix, or the vapor retardant that was placed underneath the concrete was faulty, a major moisture problem could be hidden within the concrete. For this reason, moisture tests should always be performed prior to the application of any coating system.

What is Moisture Testing or Calcium Chloride Testing?

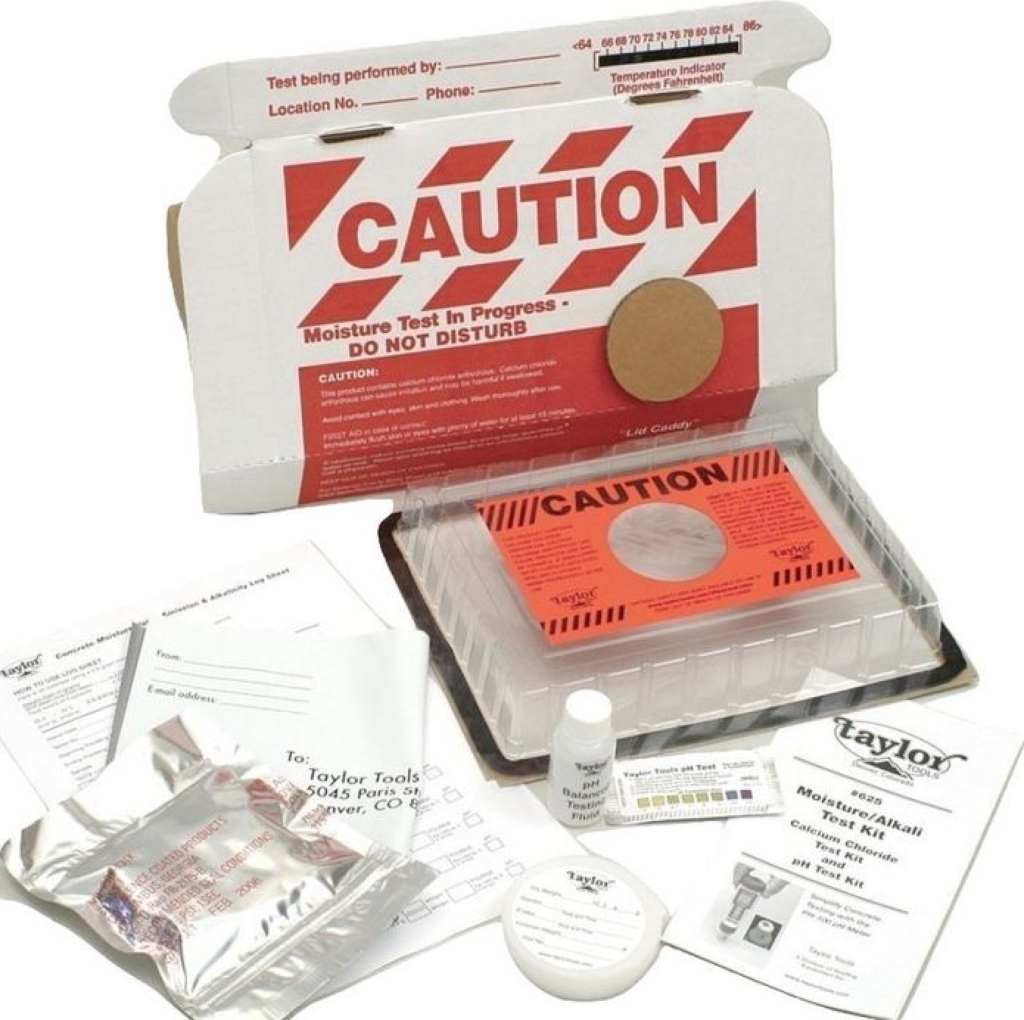

Professionals can administer several tests to determine the moisture levels in your slab before installing an epoxy floor coating. The Calcium Chloride Test, Plastic Sheet Test, and RH tests are the most common, with the Calcium Chloride Test being the most popular. It is critical that you choose a seasoned professional to administer these tests to ensure that proper steps are taken.

The Calcium Chloride Test is one of the most well-known tests that measures the moisture vapor levels in a concrete slab. It is the standard test used by the majority of flooring contractors in the United States. The calcium chloride moisture vapor emission test was developed in the 1950s to quantify the volume of water vapor emitting from a 1,000-square-foot area of concrete slab surface over 24 hours. This testing helps you determine if you need a moisture vapor barrier. Per ASTM F1869, test density is required to equal 3 tests in the first 1,000 square feet, with one additional test for each additional 1,000 square feet of the concrete slab surface. Proactively testing the concrete prior to the installation of flooring may prevent the considerable losses attributed to excessive moisture vapor emission and related floor covering system failure.

The American Society for Testing and Materials (ASTM) states that Moisture Vapor Transmission Rates (MVTR) of four pounds per 1000 square feet over a 24-hour period is the maximum rate allowable to successfully cover concrete with adhesives, sealers, or coatings. MVTR can be determined by comparing the weight of the calcium chloride in the test before and after the test time (60 to 72 hours), it indicates not just whether moisture is present, but the quantity and MVTR traveling upwards through the slab.

How do the Professionals Deal with MVT?

Not all coatings for concrete offer the protection that you need to fight MVT-related damage. In DIY epoxy flooring installation projects, refer to your product data sheets to learn the MVTR that each specific product can handle. The suggested test methods and limits from product manufacturers should be adhered to for the best outcomes.

In most situations, the professionals tackle moisture problems in concrete floors by using a moisture vapor barrier primer. The moisture vapor barrier helps reduce the passage of fluids through concrete. It successfully relieves the problems associated with moisture vapor in a concrete slab, keeping moisture from reaching the epoxy flooring system. The thickness of the primer used is based on the amount of moisture present in the concrete. The good news is that newer floor coating products and proper installation techniques will reduce or eliminate water vapor transmission problems.

Concrete failures can happen due to high moisture levels at any time, especially in areas like Alaska. Unfortunately, not everyone is experienced or has the proper equipment to test their concrete. At GH Alaska, LLC, we test concrete for moisture in accordance with ASTM F1869 (using Calcium Chloride Testing). To get the job done right, call our team of experts at 907-414-4941.

View article on MakeASceneak.com: https://www.makeasceneak.com/june-2022/2022/6/15/concrete-moisture-vapor-what-you-should-know?rq=epoxy